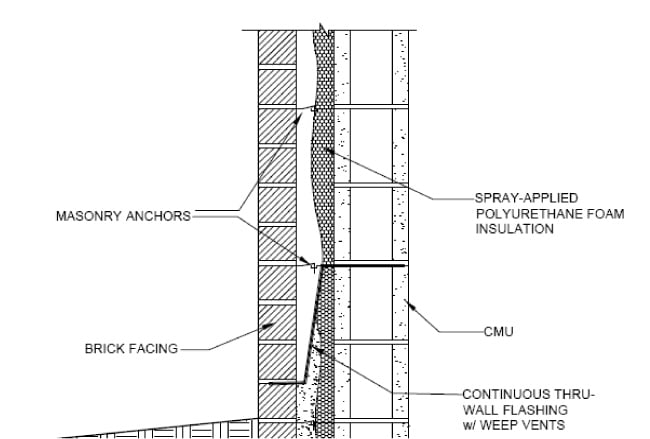

Spray Foam Air/Moisture Barrier Systems

Air Barriers control the unintended movement of air into and out of a building enclosure. Spray Foam systems provide the highest level of thermal insulation and provides a monolithic, fully sealed air and moisture barrier. Its spray applied installation process speeds construction and reduces labor costs substantially (estimated up to $1/square foot).

Benefits include:

- Seamless

- Fully-adhered

- Conforms to irregular shapes (masonry anchors)

- Strengthens the building structure*

- Cost efficient (est. $2.50/ SqFt vs. $3.50/ SqFt standard air barrier system)

- Thermal Barrier – R-7/ inch

- Energy efficient*

Estimate air leakage deduction by up to 83%

Reduce gas bills by more than 40 percent

Reduces electrical consumption in excess of 25 percent - Increased air quality due to lack of air infiltration, reduced allergens and pollens entering the building*

- Qualified LEED Certification credits as a green building product*

Spray Foam Air Barriers Provide Continuous Coverage and Insulation around anchors to the Exterior of Buildings

Spray Foam Air Barriers Provide Continuous Coverage and Insulation around anchors to the Exterior of Buildings Monolithic, Fully-adhered Spray Foam Air Barrier Being Applied to Exterior of Building Before Face Brick

Monolithic, Fully-adhered Spray Foam Air Barrier Being Applied to Exterior of Building Before Face BrickSpray Polyurethane Foam System

2 inches (R-14) estimated cost of labor and materials - $2.50/square foot

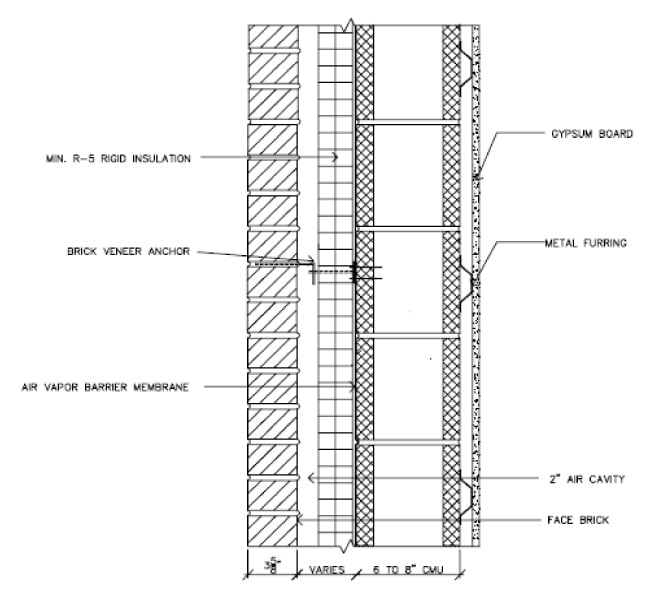

Standard Air Barrier System

2 inches Rigid Board Insulation (R-10) and liquid applied air barrier estimated cost of labor and materials - $3.50/square foot

* According to simulations by the National Institute of Standards and Technology (NIST) of typical buildings without air barriers: Available Here

* 18 Page Honeywell® whitepaper Air Barriers in Building Construction: Understanding Costs, Meeting Performance Standards and Exceeding Codes: Available here

I have worked with built-up asphalt, single-ply and SPF roofing. SPF is far superior to other roofing systems.... Robert T. Stetson, P.E.